Fashion is suffocating the earth. Quite literally. Every second, a garbage truck loaded with textile waste turns up at the incinerator or the landfill. And annually, these global trash dumps emit more than 100 million tonnes of planet-warming methane, a gas 25 times more potent than carbon dioxide. Pretty much every industry in the world is overflowing with waste and contributing to this mess. But as the second largest polluter globally, fashion has a duty to do something urgently.

Fast fashion brands depend heavily on promoting overconsumption. And in the luxury space, brands destroy and throw away their own unsold goods to maintain exclusivity and value. Both sectors have trouble with managing faulty items and returns, 10 percent of which are sent to the landfill. This already feels like so much waste. But it doesn’t stop there. A monumental amount of fabric is wasted before garments have even made it to the rack.

Around 15 percent of every production run isn’t used. And this means that every year, $120 billion in unused textiles is either sent to the landfill, incinerated, or simply left sitting in the warehouse, untouched. But there is a way to rectify this situation. Unused fabric from mills and factories, known as deadstock, is a sustainable resource in the fashion industry. It can be salvaged, sold on, and made into new designs, keeping more textiles out of the landfill for longer. But right now, it seems that the industry is overlooking deadstock’s potential.

Millions of tons of deadstock is wasted, but it doesn’t need to be that way

Much of fashion’s waste problem is hard to solve. Post-consumer garments are not easy to recycle, because this involves materials being separated. But often, clothes are made with a blend of synthetic and natural fabrics, like polyester and cotton, and there are things like elastic, zips, and buttons to consider. But yarns of fabric that haven’t been blended or sewn into complicated garments yet are much easier to divert from the landfill.

Last year, textile tracking and trading platform Reverse Resources conducted an extensive investigation into factory textile waste. The platform predicted that the fashion industry is wasting around nine million tons of textiles every year that could be rescued and made into something new. In other words, there’s a heck of a lot more deadstock being sent to the landfill or the incinerator than there needs to be.

“There’s a percentage of waste material that is actually fine for reuse,” agrees Stephanie Benedetto, the founder of deadstock marketplace Queen of Raw. “That’s as well as the material that was ordered and never used, or excess sample yardage. But historically there has been no avenue to resell it. So it winds up being indefinitely warehoused, or burned.”

Millions of tons of deadstock is created because the world’s biggest fashion brands have a huge overproduction problem. It all began in the nineties and 2000s, when fast fashion giants Zara and H&M were starting to open stores around the world. This duo and companies like them birthed a business model that prioritized fast and cheap production above all else. Now, we’re living in a time when brands make thousands of garments every month to keep up with the marketplace. And all of those designs leave wasted offcuts behind. Remember: 15 percent of every production run isn’t used. “They churn through new styles to make more, faster,” says Benedetto. “That’s what has led to the sheer volume of waste.”

Brands need to dismantle and rebuild their business models. Sustainability is incompatible with overproduction. But until that happens, brands can at least try to minimize their impact by making use of all the deadstock they create. And if anything’s going to motivate them to do so, it’s profits. “Covid has caused a crisis of supply and fundamental uncertainty,” says Benedetto. (She’s not wrong: In Europe, the first year of the pandemic saw clothing sales decline by more than 43 percent.) “So having 15 percent of your bottom line eaten up by waste is something that brands can’t afford to do any more,” she adds.

Benedetto is leading the way in showing the fashion world just how profitable deadstock can be. Queen of Raw buys up rolls of unused or rejected fabric, and sells them directly to a customer base of 500,000. Some are individuals looking for cheap materials, others are fashion students, while many are emerging small designers and brands. It also sells to Fortune 500 companies, via a resale engine called Materia MX.

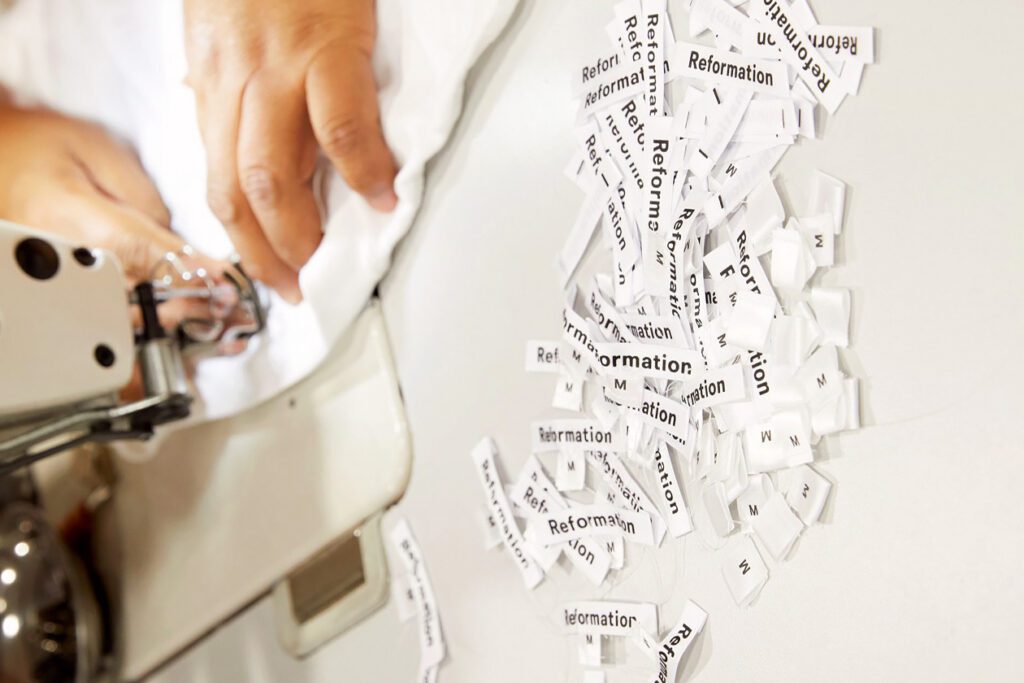

Queen of Raw is not alone. Fabcycle, Reformation, Christy Dawn, and OhSevenDays are all examples of brands utilizing or selling on rejected or unused fabric from factories. In fact, the upcycled textiles market is growing. By 2027, it could reach a value of $7.6 billion globally.

The problems with using deadstock in fashion

On the surface, using deadstock seems like a straightforward way to minimize textile waste. But the solution has its drawbacks. Selina Ho, the founder of sustainable fashion consultancy ReCloseted, is a fan of deadstock. But she’s wary that some are cashing in on demand for surplus fabrics, and they are exacerbating, not helping, the textile waste crisis.

As outlined earlier, a lot of deadstock comes from brands overproducing. Ho says some factories take advantage of that, and intentionally produce even more in order to sell fabric to “jobbers.” These are middlemen fabric suppliers, who build a profitable business model around reselling surplus fabric, thus creating more supply and demand for overproduction. In this sense, the excess fabric isn’t really deadstock. It’s just more available stock produced by the factory. To be true deadstock, the fabric should have been rejected or left unused by brands.

Research is limited in this area, and it’s difficult to quantify just how much this is happening. But it’s worth noting that buying and selling surplus fabric isn’t restricted or regulated by any external body, and it’s down to brands to trace their supply chains to ensure factories are being responsible. “There is a general fabric overproduction problem going on,” says Ho. She added that it’s vital that brands “dig deeper and ask questions, even if it’s deadstock fabric that, at the surface level, sounds sustainable.”

Megan Mummery, the founder of OhSevenDays, used to source from fabric middlemen. But now she is digging deeper. She goes directly to the mills, a step that she says allows her more visibility over the entire supply chain. “We said, ‘look this is our model, do you have leftover quantities that we can get directly from you?,’” she recalls. “Rather than going to the middleman and not knowing where the fabric came from. So now we can have a little bit more transparency around our sourcing.”

But there are also problems with the fabric itself to overcome. Genuine deadstock can often be rejected because it’s damaged. “Sometimes, there’s a couple of holes here or there so they can’t really sell it,” explains Mummery. “They call it second quality fabrics.”

She’s careful about her sourcing process; OhSevenDays designs incorporate durable, high-quality sustainable materials, like tencel, cupro, and linen. But ultimately, Mummery admits it’s tricky making clothes this way. “It’s an ongoing struggle,” she says. “You never quite know how to lie the patterns down, or how many pieces are going to end up with faults and how many aren’t.”

Deadstock is not perfect, but it’s better than the landfill

By design, deadstock isn’t without its flaws. But for Benedetto, it represents hope in an industry that is turning into one big ugly pile of waste. Because as well as taking up space in landfills, fashion is quite literally soaking up the world’s water supply. The entire market uses around 93 billion cubic meters of water a year. To break that down further: it takes 7,500 liters of water to make just one pair of jeans.

It might be extra work for brands, but keeping genuine deadstock in circulation can help reduce fashion’s water reliance considerably. According to Queen of Raw, purchasing just one yard of fabric from its marketplace saves 700 gallons.

“The possibility space is massive for everyone, from the startup to the big business,” says Benedetto. “For me, deadstock material is probably the most powerful untapped sourcing mechanism there is. Ignoring it is ignoring an easy way to start moving towards the future the fashion industry and the world needs.”

And when garments do come back damaged because of faults in the deadstock fabric, brands can get creative. They don’t have to throw them in the trash and create more waste. OhSevenDays’ Zero Waste Misfit range offers clothes with stains, rips, or marks for discounted rates, for example. “I was like, ‘this is crazy that such a tiny thing will make this perfect garment go to trash,’” says Mummery. “In my mind, having an area where people can shop for tiny little faulted items makes so much more sense.”

There’s a long road ahead for the fashion industry when it comes to waste reduction. And each step is going to involve acceptance: that it’s producing too much, that the planet and humanity can’t cope under the strain, but also, that, when it comes to building a more planet-friendly future, waste is one of its most valuable assets.