Dole Sunshine Company (the world’s largest producer of fruit and vegetables) just announced a partnership with Ananas Anam, the UK-based owners of vegan pineapple leather brand Piñatex.

Ananas Anam will use leaf fibers collected and extracted from one of Dole’s farms in the Philippines—home to some of the largest plantations in the world—in its Piñatex products. The partnership marks a significant step towards Dole’s goal of zero produce loss by 2025.

“Addressing food waste is absolutely important to us, as it is connected to our business and our lives in so many ways,” said Pier-Luigi Sigismondi, the global president of Dole Sunshine Company. “I believe to create tangible solutions and real systemic change to address this issue, we need to converge our purpose with creativity, innovation, and technology.”

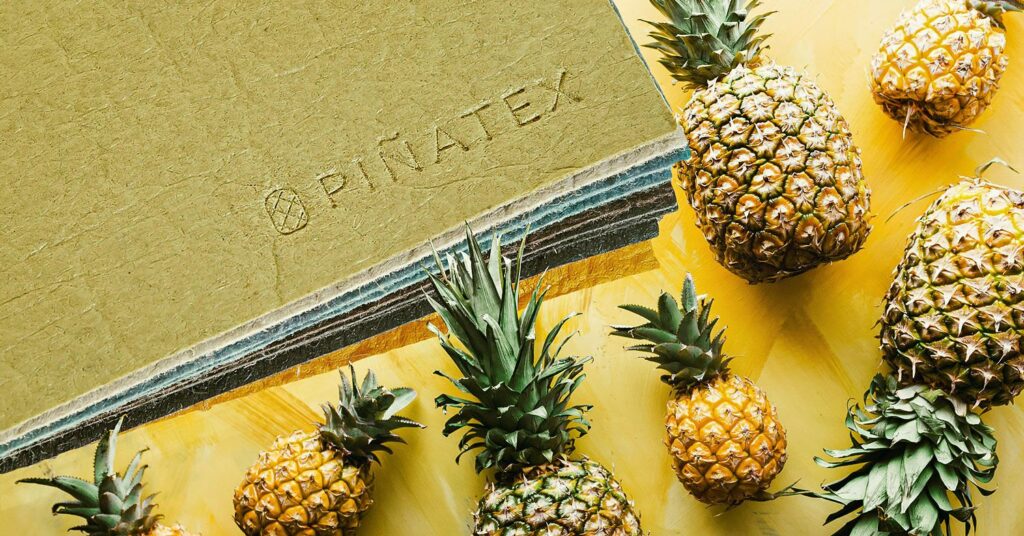

Dole x Piñatex: turning fruit waste into vegan leather

Food waste is a huge problem, and easily damaged fruit makes up a disproportionate amount of unnecessary spoilage. Approximately 45 percent of all produced fruit and vegetables ultimately go to waste. And as one of the top two pineapple producers in Europe and North America, Dole is also one of the biggest generators of this waste.

Typically, the industry burns pineapple leaves or sends them to landfills, contributing to the production of CO2, methane, and other harmful emissions. By using pineapple leaves as a base for the production of its patented fabric, Piñatex simultaneously removes them from the waste stream and provides a sustainable alternative to high-polluting and destructive traditional leather.

The sheer scale of Piñatex and Dole’s new partnership also presents a unique opportunity for the companies to support developing farming communities and simultaneously increase output to match growing global enthusiasm for vegan leather.

“Through our partnership with Dole, our entity in the Philippines will access a much larger volume of pineapple leaf fibers, to meet the ever-increasing demand for Piñatex not only in fashion but also in the upholstery and automotive sectors,” said Melanie Broye-Engelkes, CEO of Ananas Anam.

Dole is also working to use ‘ugly’ produce in snacks, drinks, and juice powders to ensure it doesn’t go to waste, while turning banana leaves and other inedible byproducts into sustainable, biodegradable packaging for its fruit and vegetables. The company aims to eliminate plastic packaging from its entire line, also by 2025.

How pineapple leather is made

Because Piñatex makes pineapple leather using waste leaves (an inevitable byproduct of the existing industry) it requires no additional environmental resources for production. In addition to reducing organic waste, the finished product is more sustainable than both traditional leather and harmful vegan alternatives such as PVC.

Piñafelt, the base of all Piñatex’s leather products, is a mixture of dried leaf fibers and a corn-based acid. The company then finishes, colors, and coats this non-woven mesh for strength and durability.

So far, major brands such as Nike, H&M, Paul Smith, and Hugo Boss have all incorporated Piñatex materials into their products. The Hilton Hotel London even partnered with the pineapple leather producer to introduce the world’s first all-vegan suite.

Around the world, consumers and producers alike are moving away from traditional leather in favor of vegan alternatives (such as mushrooms, cacti, pineapples, and other fruit) for the sake of the environment and animal welfare.

Check out LIVEKINDLY’s guide to vegan leather here, or learn more about sustainable fashion here.